Insights > Category > Posted: 2022-Jun-28, Updated: 2025-Mar-31

Glass Performance

Gas Between the Panes

Does it really matter?

Yes, it does! The right gas can help maintain a consistent temperature inside your home, reduce energy consumption, and improve insulating properties. It's crucial to consult with a professional to determine the best gas for your windows and to ensure that they are installed correctly.

The history

Multi-paned (multi-glazed) windows, made up of two or more glass panes, form a single-window system known as insulated glass units (IGUs). Invented in Scotland during the Victorian age, the original double-paned windows were naturally filled with air. Today, sophisticated manufacturing technologies fill the space between the panes with various types of gases, enhancing the IGUs in many ways.

In the early 1970s, window companies began experimenting with noble gases to tackle soaring energy costs. They theorized that denser-than-air gases would increase a window's insulation value.

Going green

In today’s ever-changing technological world, homeowners are becoming more conscious of energy costs while embracing the trend of bringing more natural light into their homes. However, windows are typically the weakest insulated spot in a house. The benefits of improved outdoor views, better lighting, and openness often outweigh the potential energy loss for many homeowners. This is a concern considering that windows currently only achieve an R-value of about 4, compared to solid walls, which rate between an R-value of 30 to 40.

How does gas work?

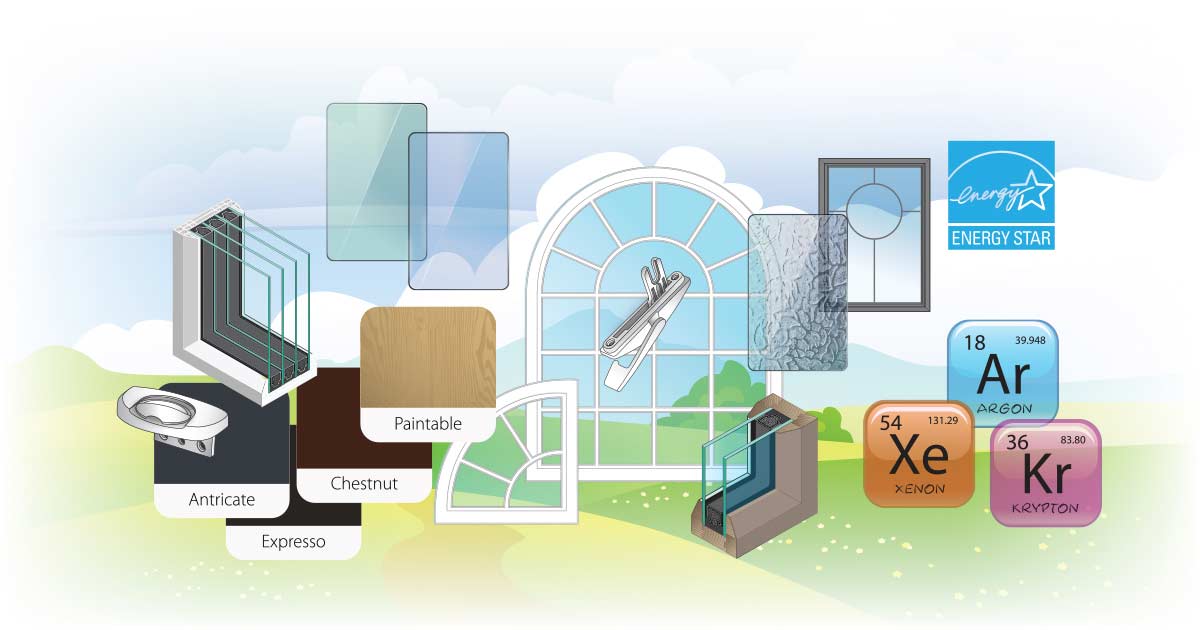

Gas in glass acts as an insulator, working in both summer and winter to keep interiors protected from outside temperatures. The denser the air space between the glass, the better the insulation properties. Inert (noble) gases like argon, krypton, and xenon are used to fill the spaces between glass panes, transforming ordinary glazing into draft-defying superglass. In addition to improving comfort, insulated windows reduce noise pollution and limit harmful ultraviolet rays from entering the home.

The Impact of Gas Density on Energy Conservation in Windows

The type of gas used between the panes of insulated glass units (IGUs) significantly impacts their energy conservation capabilities, primarily due to the varying densities of the gases. Denser gases provide better insulation by reducing heat transfer more effectively than less dense gases.

- Air, with a density of 1.2922 g/L, was initially used in double-paned windows but offers limited insulation.

- Argon, with a density of 1.784 g/L, is a popular choice for modern IGUs because it provides approximately 30% better thermal insulation than air while being cost-effective.

- Krypton, with a density of 3.749 g/L, offers superior insulation compared to argon, making it ideal for triple-paned windows or windows with narrower gaps between panes. Its higher density reduces thermal conductivity, enhancing energy conservation.

- Xenon, with a density of 5.894 g/L, provides the highest level of insulation due to its significant density. Although it offers marginally better energy savings than krypton, its high cost limits its use in residential applications.

By selecting the appropriate gas based on its density, homeowners can optimize the thermal efficiency of their windows, leading to reduced energy consumption for heating and cooling and ultimately contributing to lower energy bills and enhanced comfort.

Is this gas harmful?

The gases used to fill window IGUs (argon, krypton, and xenon) are inert (non-reactive) and occur naturally in the Earth’s atmosphere. Argon, the most common, comprises about 2% of the air we breathe. Both krypton and xenon are very rare and need to be extracted from the air before they can be used in window manufacturing. These gases also provide superior soundproofing compared to air fills.

Argon

Argon, which makes up slightly less than 1% of the Earth’s atmosphere, is non-toxic, inert, clear, and odourless. It is the industry standard for filling double-glazed IGUs because of its cost-effectiveness and energy efficiency. Argon offers thermal conductivity around a third lower than air for only a marginal cost increase. It excels at reducing heat gain during summer while keeping interiors cosy in winter. IGUs filled with argon are also less prone to interior condensation due to argon's lower moisture content compared to air.

Krypton

Krypton is more than twice as dense as argon and is ideal for triple-paned IGUs where the total glazing unit thickness must be minimized. In gaps wider than 20mm, convection currents can form, reducing krypton's effectiveness. Krypton is extremely rare, making up just 1 part per million by volume, and is extracted through air distillation. It is about 100 times more expensive than argon. Despite its superior energy performance and potential to significantly reduce monthly energy costs, the high price of krypton-insulated windows makes them prohibitive for many homeowners.

Xenon

Xenon insulation represents cutting-edge window technology and costs significantly more than both argon and krypton, with only slightly better energy savings. Due to its high cost, xenon is rarely used in residential homes. It sits at the forefront of glazing technology and is generally not worth considering unless you're planning to build a home with extensive glass use.

Even better results

Window manufacturers often combine gases with low-emissivity (low-E) coatings on glass panes to keep the interior glass temperature closer to the interior air temperature, minimizing air currents created by temperature differences.

What about leaks?

Gas-filled windows will leak over time, with some estimates suggesting up to 1% per year. This depends on the quality of the window, its installation, climate, and sun exposure. However, even after 20 years, a window with a slow leak will still perform well with an 80% gas fill. Reputable manufacturers certify their products to ensure minimal leakage. In Canada, the AAMA certification label indicates a product conforms to the standards of the Certified Products Directory (CPD), the industry’s preeminent resource for window and door products.

How do you know when an IGU is running out of gas?

Condensation or fog (or white residue) inside the window unit indicates that the gas fill has escaped and been replaced with moisture-laden air. Leaked argon, krypton, and xenon pose no health hazards to a home’s occupants.

What should I look for when buying gas-filled windows?

To get the best value, ask your window company for warranty details on gas-filled IGUs. Look for a company that warrants the units for life (25 years) with no installation charges for replacing failing IGUs. This indicates a quality, no-hassle product.

Related stories

Need more information?

Unlocking the full potential of your home's energy efficiency starts with understanding the right gas fills for your windows. This vital information often gets overlooked, but we're here to help. Reach out to us for detailed insights on the gases used in our products. Our expert team is eager to answer your questions and guide you toward the best choices for your home. Don't miss out on maximizing your comfort and savings—contact us today!