Insights > Article > Posted: 2025-Mar-20, Updated: 2026-Jan-13

Energy-Efficient Entrance Doors: Keeping Your Home Comfortable vs Lower Energy Costs

In this article:

- Energy efficiency and entrance doors

- Comparing material & energy efficiency

- Components that affect energy efficiency

- NFRC, NRCAN & Energy Star®

- Certified Energy Star® Doors

- Energy Star® resource links

- Proper installation

- Steps for maximum energy efficiency

- Compare products at NRC

- Related articles

- Installation - Entrance doors

- Request a free quote

Energy efficiency and entrance doors

Replacing an entrance door is a great way to enhance a home’s curb appeal, and it also provides an opportunity to improve energy efficiency. Energy-efficient doors can lower energy bills, maintain consistent comfort throughout the home, and perform well in both hot and cold climates.

Whether solid or featuring glass panels, these doors help control temperature transfer, reduce drafts, and contribute to lowering your home’s carbon footprint. They can also let in natural light when designed with glazing, without overheating the interior, and help reduce fading of furniture over time. In regions with extreme temperatures, like Ottawa, old or poorly insulated doors can allow heat to escape in winter or let cooled air leave the home in summer, increasing energy costs and contributing to global warming.

While doors themselves don’t use electricity or fuel, choosing energy-efficient doors helps reduce the energy required for heating and cooling a home. In Canada and the US, the Energy Star® program provides unbiased testing, certification, and energy ratings for doors that meet strict technical standards for efficiency.

Comparing entrance door materials and their energy efficiency

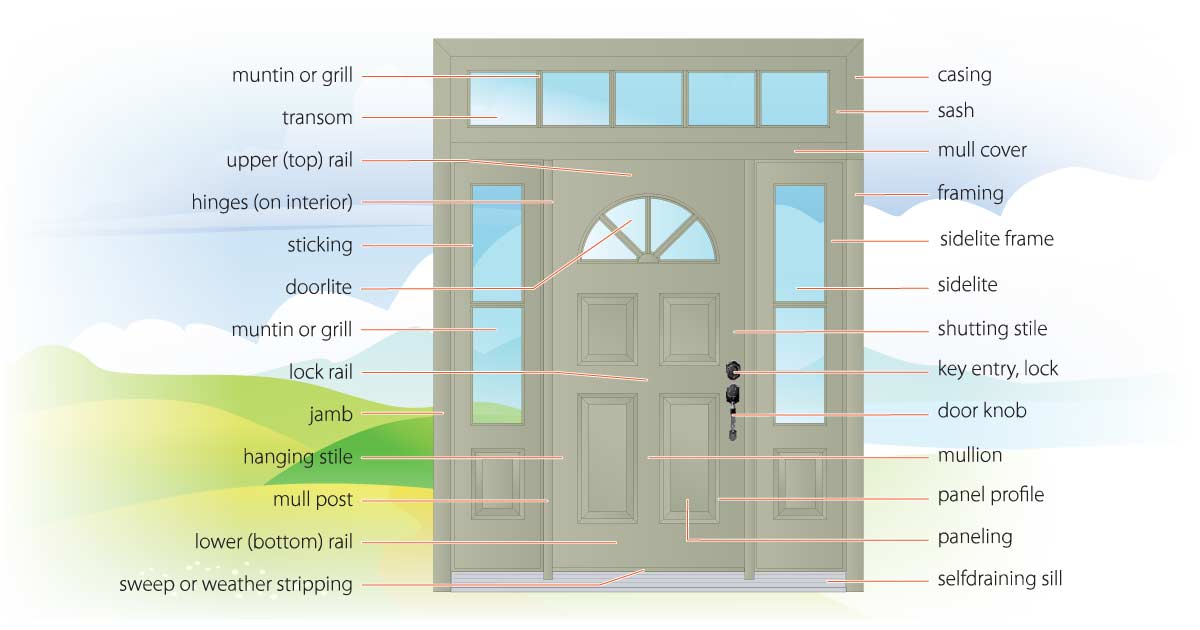

Most entrance doors are sold as pre-hung units, which include the door slab, frame with sill, hinges, and hardware. For maximum energy efficiency, it’s best to replace the entire unit, not just the door.

Doors are categorised by the material of the door slab, not the frame. Metal and fibreglass doors have metal or fibreglass skins over a reinforced frame with insulation, while wood doors are typically solid wood with no interior insulation.

Even with improvements in insulation (up to about R7), doors are still far less efficient than a solid wall in a home, which typically has an R-value of around R13.

Fibreglass or vinyl doors (R-value between R5-R7)

Fibreglass and vinyl doors are top performers when it comes to energy efficiency. With a polyurethane-insulated core that is up to six times more efficient than solid wood, they help keep indoor temperatures stable year-round by blocking heat and cold transfer.

Both materials are durable, low-maintenance, and available in many styles. Fibreglass lasts longer and can mimic the look of real wood, while vinyl offers a more affordable option that still provides excellent thermal performance. From smooth modern finishes to realistic woodgrain textures and decorative glass inserts, these doors combine comfort, efficiency, and style.

Steel or aluminium doors (R-value between R5-R6)

Metal doors conduct heat, which makes them more prone to transferring outside temperatures into the home. In extreme weather, you may even feel the temperature change on the inside surface of the door.

Steel and aluminium doors come in many colours, styles, and levels of quality. They are popular with builders because they are generally less expensive than fibreglass or wood. However, not all metal doors are the same. Some offer better insulation than others. Always look for the Energy Star symbol and compare efficiency ratings before buying.

Metal doors were once the most common option on the market. While many are still energy efficient, they do not perform as well as fibreglass doors when it comes to overall insulation.

Wood doors (R-value between R2-R3)

Solid wood doors absorb heat more easily than metal or fibreglass and allow outside temperatures to pass into the home. They are considered the least energy-efficient option, with an R-value typically less than half that of an insulated steel or fibreglass door.

Wood doors are beautiful, but faux wood fibreglass doors offer a similar look, better insulation, and lower cost. They will not rust, fade, warp, or dent, and they do not require staining or painting. If you prefer real wood, choose a thicker solid-core door for improved insulation, as a thicker door increases the R-value.

Components that affect energy efficiency

While the door slab, which is the door by itself, is the largest surface to consider for energy efficiency, the frame, insulation, weatherstripping, and glass if used are equally important. All components must work together to achieve optimal performance. If any part has weaker insulating properties, it can reduce the door’s overall R-value and U-factor. For the best results, consider the entire door system when shopping for energy-efficient doors.

Glass and glazing

Glass panels can reduce a door’s energy efficiency, but some options help improve insulation. Low-emissivity coatings reflect heat back to its source, keeping interiors cooler in summer and warmer in winter. Thicker glass improves thermal performance, and double or triple glazing adds insulating barriers with low-conductivity gases between the panes. Plastic thermal frame breaks around the glass also reduce temperature transfer from the glass to the door.

Core insulation and door framing

Metal and fibreglass doors usually contain a rigid polyurethane foam core. This core strengthens the door and helps maintain indoor temperatures. Framing materials such as metal, composite, or wood also affect energy performance because each conducts or absorbs heat differently. While framing can influence efficiency, the overall door rating should guide your purchase. Some non-solid wooden doors with foam cores provide better insulation than traditional solid wood doors.

Caulking and foam insulation

Proper installation is critical for energy performance. Installers use caulking and low-expanding foam according to manufacturer instructions to replicate the tested conditions and meet Energy Star specifications. Using inferior materials or improper installation can reduce a door’s energy efficiency.

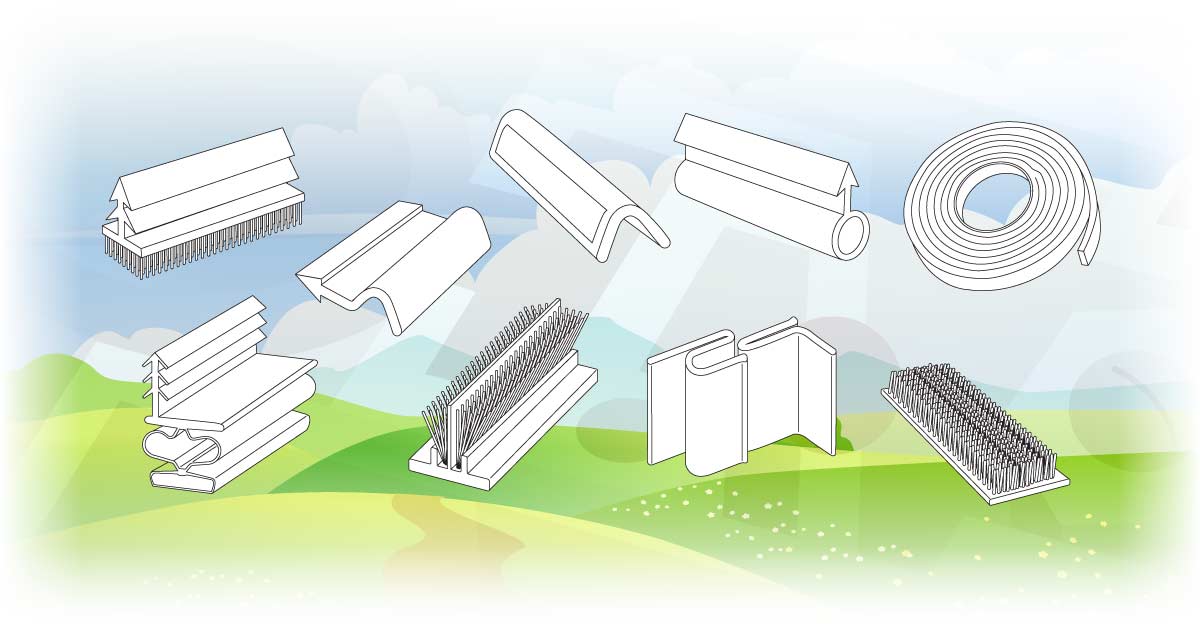

Weatherstripping and door sweeps

Weatherstripping and door sweeps seal gaps between the door and frame, preventing air leaks and helping retain indoor temperatures. Materials such as plastic, rubber, and thermoset foam cores are effective at creating an airtight seal that improves comfort and reduces energy costs.

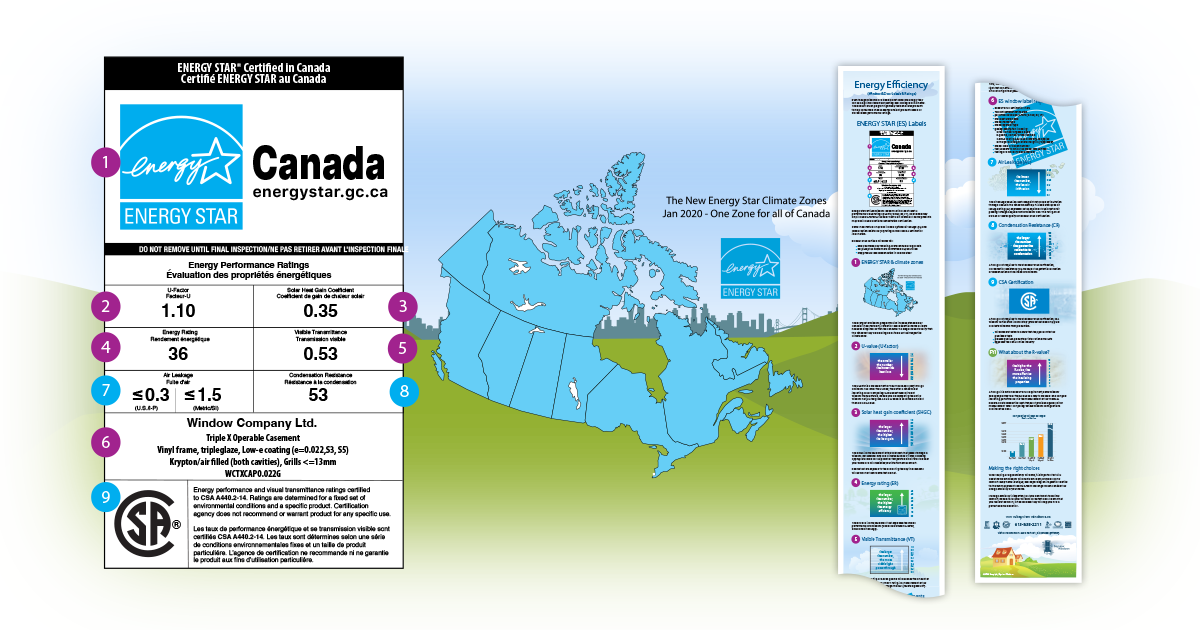

Understanding door energy ratings: NFRC and Energy Star®

In Canada, most door and window manufacturers use the Energy Star® label rather than the NFRC label, although some may use both depending on whether the product is also sold in the US. Both rating systems evaluate products based on U-factor, R-value, visible light transmittance, and solar heat gain.

In the US, the NFRC tests and rates windows, doors, and skylights, while Energy Star® certifies products that meet or exceed government efficiency standards. NFRC works to improve building comfort and energy performance.

In Canada, doors and windows are tested by Natural Resources Canada (NRC) authorised independent testers. Eligible products receive Energy Star® certification, and the ratings are published on the NRC website.

For Canadian homeowners, it is generally easiest to compare products using the Energy Star® rating when evaluating door energy efficiency.

Certified Energy Star® doors

Not all doors are built the same, and many do not qualify for the Energy Star® label. In Canada, Energy Star® certified doors are about 15 percent more efficient than the average non-certified door. These doors offer tighter seals, superior insulation, and materials designed to reduce heat transfer. The Energy Star® label is a trusted mark of high-efficiency products.

When shopping for energy-efficient doors, consider their ratings in relation to your local climate and home design. Look for the Energy Star® label to help narrow your selection.

Energy Star® qualified doors may include features such as a foam-filled insulation core, compression foam seals on the edges, thermal breaks in the frame, low-emissivity coatings on glass inserts, and professional installation by experienced companies.

In Canada, Energy Star® doors are tested using the Canadian Standards Association (CSA) A440.2 standard. Performance is rated on several metrics, some of which depend on whether the door has glass:

U-factor

Measures heat transfer from warm to cold areas. Lower numbers indicate better energy efficiency.

R-value

Measures resistance to heat transfer. Higher numbers mean greater efficiency.

Energy rating

Combines U-factor, solar heat gain, and air leakage. Higher numbers indicate better overall performance.

Coefficient of solar heat gain (SHGC)

Shows how much solar heat passes through a door. Higher numbers mean more heat gain.

Visible transmittance

Indicates how much light passes through glass. Higher numbers mean more light.

Centre-of-glass rating

Measures only the glass portion of the door. Lower numbers indicate better efficiency.

Condensation resistance

Optional rating showing how well the door resists condensation. Higher numbers indicate better performance.

Certified Energy Star® doors help homeowners improve comfort, reduce energy costs, and maintain better indoor temperatures year-round.

Energy Star® resource links

Not every home in Canada requires the same window or door performance. Northern regions experience colder temperatures and harsher winters, while southern regions have milder climates. In 2020, Energy Star® simplified its climate zones by merging three separate zones into one, which raised the efficiency requirements for southern regions.

Proper installation matters

Even the most energy-efficient door will not perform well if it is not installed correctly. Professional installers have the tools, training, and expertise to prevent cold drafts, water leaks, and condensation that can reduce the door’s performance.

Pre-hung doors are delivered as a complete unit, typically with a wood or steel frame and pre-installed weatherstripping. It is important to choose an installation company with a strong reputation and proper certification, such as Window Wise.

Door installation steps for maximum energy efficiency

1. Inspect the rough opening for gaps or damage and seal any air leaks before installing the new door.

2. Remove the existing door frame from the rough opening.

3. Place the new pre-hung frame and square it using shims and screws according to the manufacturer’s specifications.

4. Ensure the door swings properly and seals tightly against the jamb.

5. Check the sill or threshold to make sure it is properly insulated and sloped to prevent water infiltration and thermal bridging.

6. Apply a taped vapour barrier to the inside of the frame.

7. Insert expanding foam insulation between the frame and the rough opening, making sure it creates solid contact without pushing the frame out of square.

8. Inspect and seal around any side lights or glass inserts with proper insulation or caulking.

9. Apply coloured caulking to the exterior frame to prevent water leakage.

10. Install interior trim and apply caulking where the wall meets the trim.

11. Verify weatherstripping and door sweeps are properly aligned to eliminate air leaks.

12. Test the door for airtightness by checking for drafts and adjusting seals as needed.

Related articles

Need more information?

If you are looking for an energy-efficient door, choosing the

right product and the right installation company will make a huge

difference.Want to know more about energy-efficient Energy Star® doors,

please give us a call or request more information via our contact form.

We’d be happy to answer all of your questions.